Timeline and Contingency Plan

Plan:

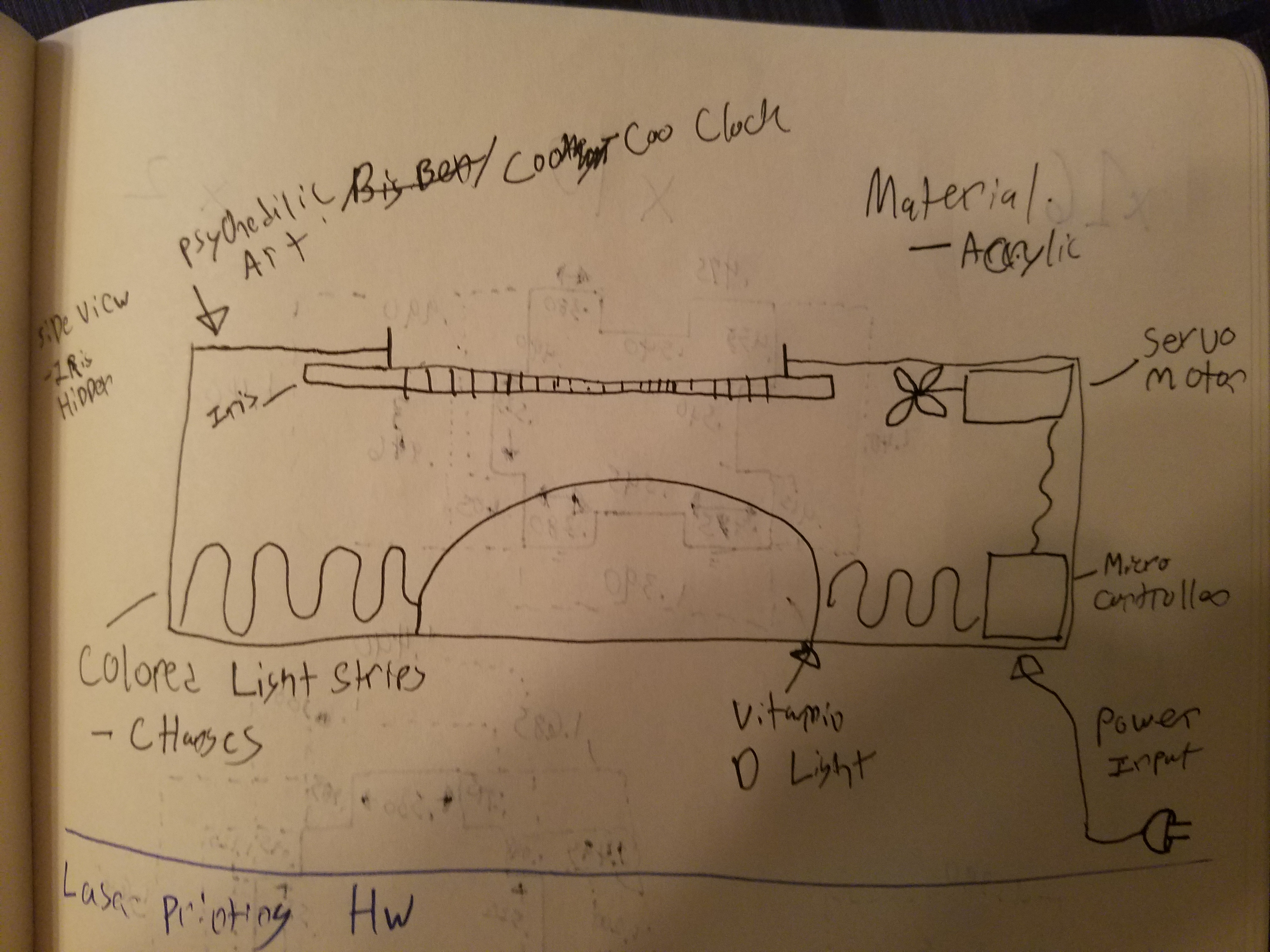

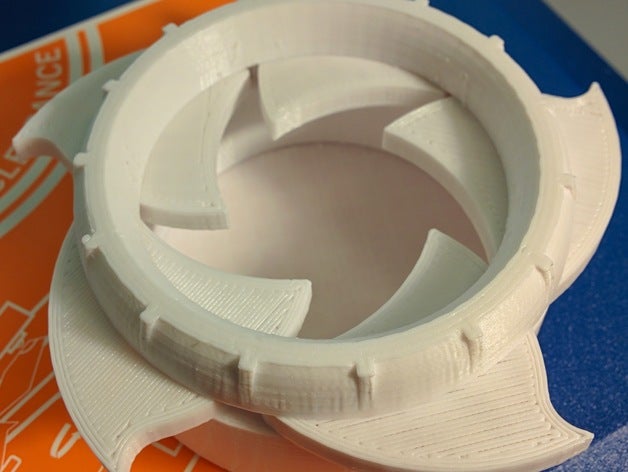

5/29 - 5/31 Print Moveable IRIS Part models

6/1 - 6/2 Cut Wood to create the Press Fit box

6/3 Merge parts to create Prototype Assembly 1.0

6/4 - 6/5 Correct for Errors.

6/6-6/7 Prep and Submit Final Assembly

Contingency Plan:

As Nadya talks about its important to Fail Fast in Digital Fabrication. As Such, I will focus on producing a high fidelity Prototype 1.0. If extra time is created due to proper planning/execution, I will develop a high fidelity prototype 2.0.