Mold and Casting Overview:

Digital Fabrication Assignment 6

After I tried making a Sextant model based on an Inspirational Sextant ,

I decided to keep it simple so I downloaded a Sextant to act as the detailed model inside the Positive Mold. ( Sextant by IESSanchezCanton is licensed under the Creative Commons - Attribution license. )

For example I learned how to convert the Stl models from Thingiverse using the Mesh to Bbodies function.

Exploded view of an early prototype with restriction points and a sprue.

The original plan was to learn more about subtractive cutting with Fusion 360 and the CNC tooling system.

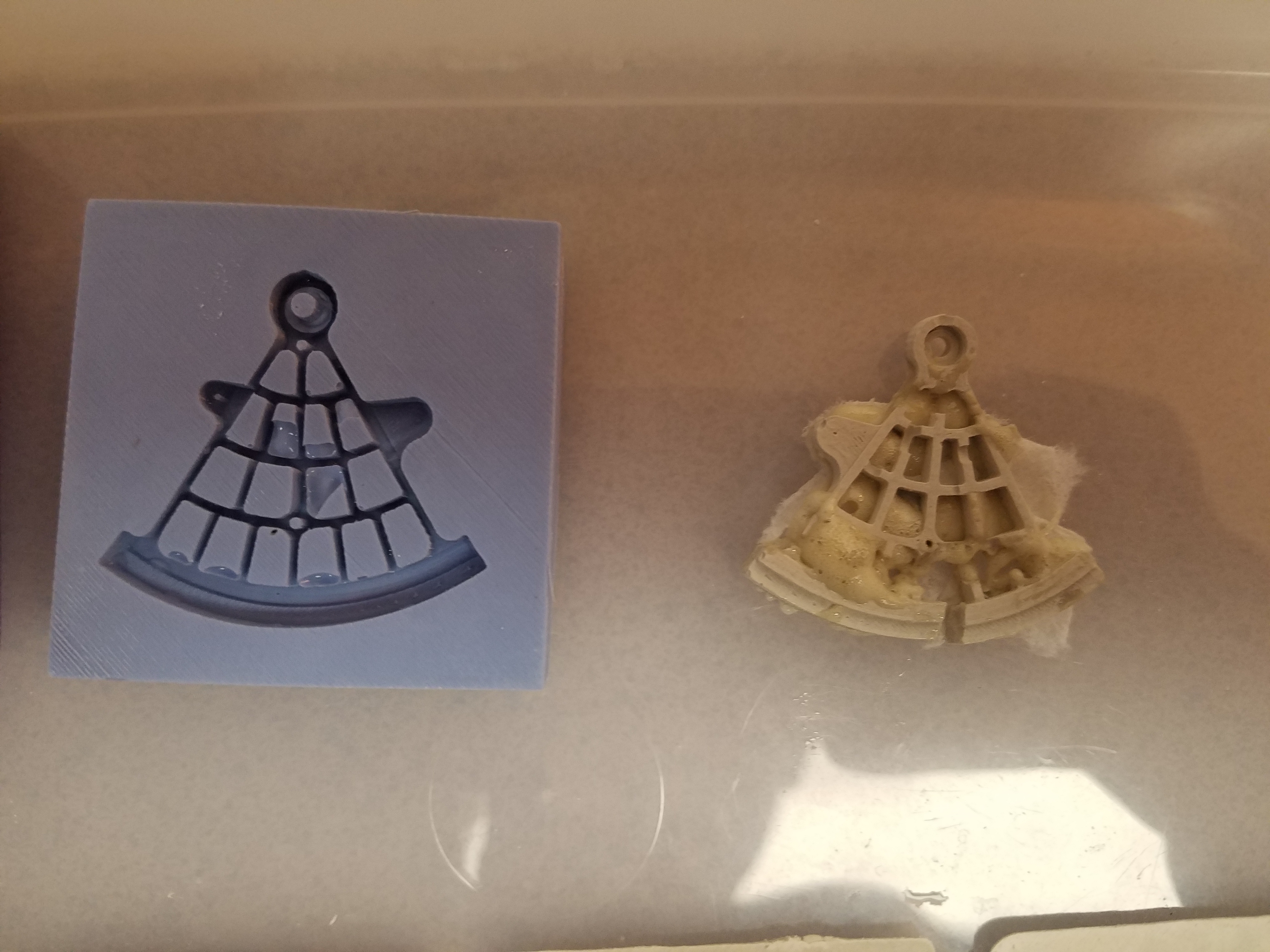

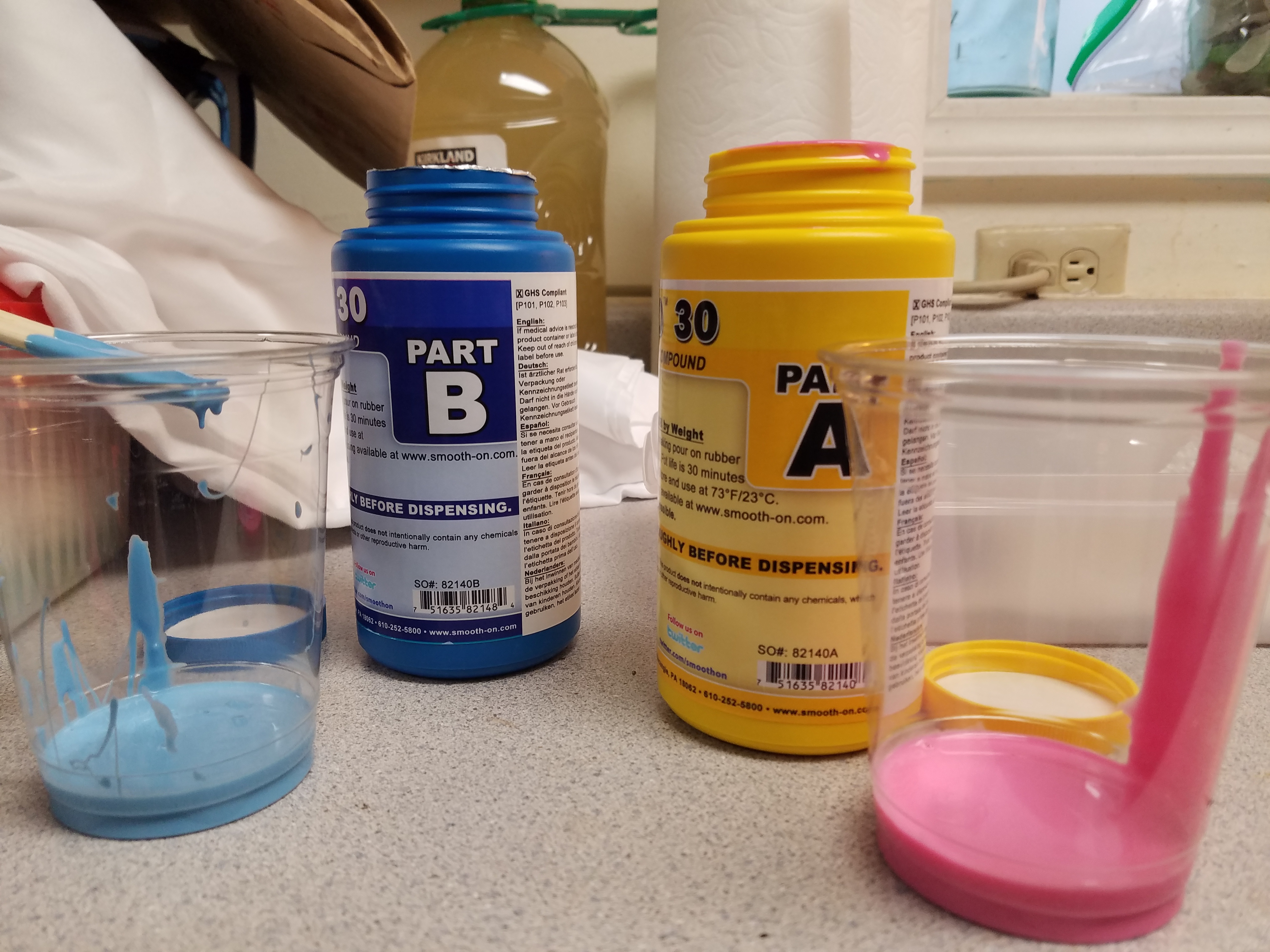

3D Printed a Positive Mold so that negative Mold could be produced with OOMOO 30

The output crumbled when removed from the negative mold.

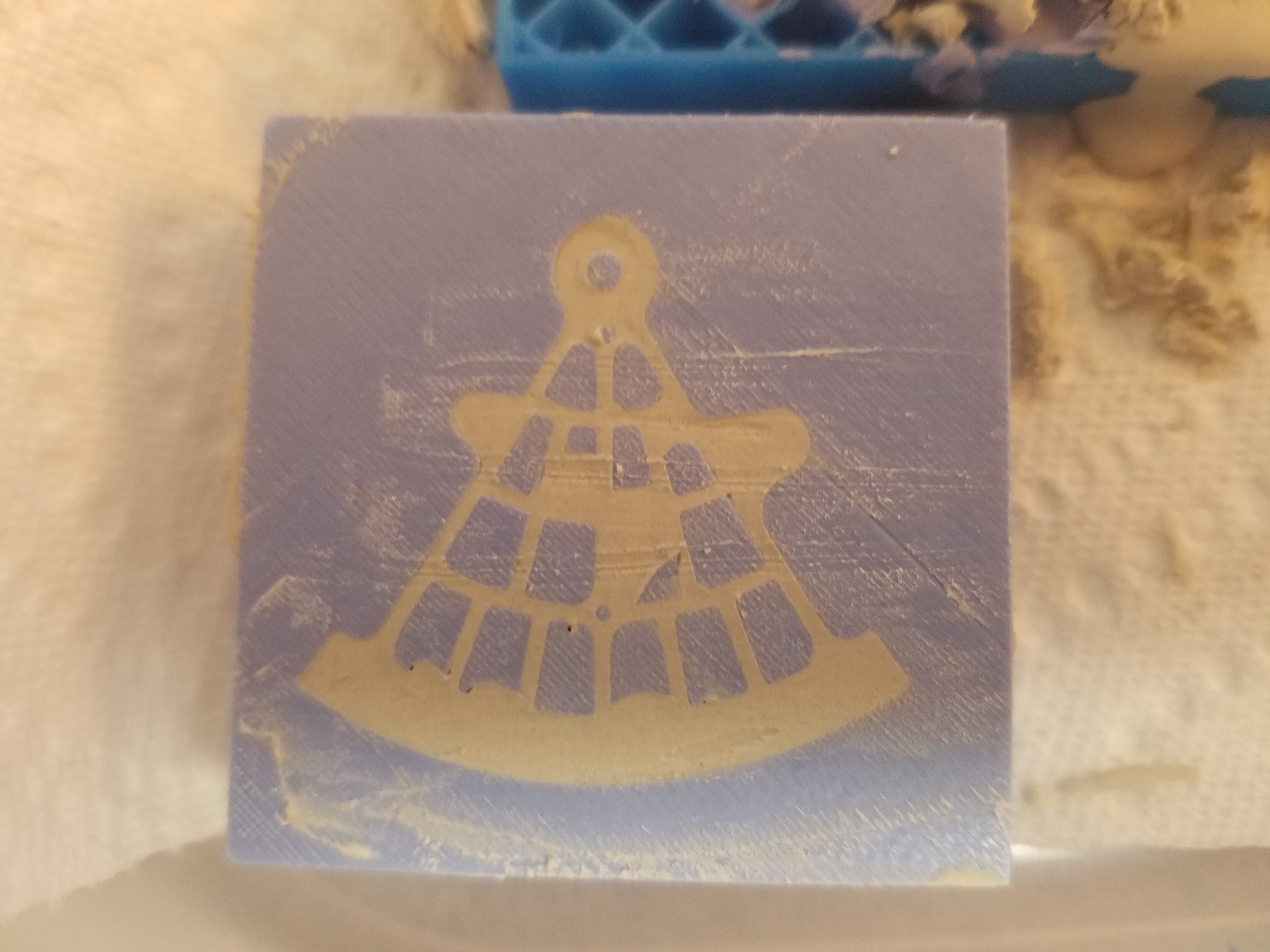

Repurposed 3D printer errors to make a double sided mold and tested its output.

Explored the use of a single sided mold and a double sided to mold to see which design produced the best results.

After testing each mold, I focused on using the single sided mold to cast the Sextants.

Final four plastered pieces fulfilling assignment requirements.

Joshua, Angel, Dhwani Vekaria, Julie Do, Peter, Andrew, Nicole, Demarcus, helped each other out with best practices.